The ArtiCAD file is often just a plan with dimensions on, usually in increments of 50, but with Cabinet Vision’s parametric capability and the parameters already set up, if I drop a 600mm unit in and change it to 587mm, all the relevant sizes and joins are all changed accordingly. “As I’ve got a library of the 60 or so cabinets that we use regularly, I create the rooms by dragging and dropping the units into the project, and then editing them. Design manager James Graves now receives each customer order as an ArtiCAD drawing from its external designer, and imports it into Cabinet Vision. So, the natural progression was to invest in Cabinet Vision for carcass work. And if a kitchen contained 600, 500 and 400mm units, I’d put them on a separate sheet and nest them through Alphacam, which was a long-winded process when compared to Cabinet Vision, because it’s not optimised for that type of work.” “So, in time, my Alphacam program had up to 150 different units. “We’d have a standard 600mm base unit with the holes and toolpaths – but if a customer wanted a 550mm unit, for example, I’d have to take it down by 50mm.

“It was taking a long time to programme our three-axis SCM Ergon machine tool,” he says.

#Cabinet vision system parameters full#

Three years ago, having worked there for over 20 years, Paul bought the company from Chris Sharp, and decided to concentrate solely on kitchens.Ĭhris Sharp Cabinets can now complete a full kitchen plan in around 20 minutesĪlphacam had been the main software for furniture production there for many years, and the company continued to use it to design and manufacture the cabinetry components for its kitchens – Paul admits that it was not the optimum tool for casework assemblies. With a long-standing history of making both softwood and hardwood furniture, the company decided it needed to diversify as cheap imports began to have an effect on business, and moved into the purely bespoke kitchen market. Having recently invested in Cabinet Vision software to complement its Alphacam package, the business has capacity for designing and manufacturing around 20 a week. Although we had to machine multiple panels, our CNC machine was running at up to 80m a minute.”Ĭhris Sharp Cabinets’ Paul Kettleborough and James GravesĮmploying a dozen people at its 15,000 sq ft workshop and showroom in Lincolnshire, the company generally produces two kitchens a week for end-users, with a number of others for property developers. “I wanted to know just how quickly we could produce a kitchen. “I did that simply to prove a point,” says Paul Kettleborough. According to Paul Kettleborough, MD and owner of Chris Sharp Cabinets, Alphacam’s Cabinet Vision software has radically streamlined kitchen production in his business, and has created so much more potential … Stage three – the following day it was cut, drilled, edged, assembled and delivered by 12.30pm.

Stage two – the material was ordered at 4.55pm the same day. This includes use of the UCS Wizard, adding, modifying and deleting parts, use of the UCS Interface and the anatomy of a User Created Standard, and advanced techniques such as adding operations to parts, and setting up variables to control objects within a User Created Standard.ģ21.238.Stage one – designing a 20-unit kitchen for a developer took a matter of minutes with Cabinet Vision.

#Cabinet vision system parameters manual#

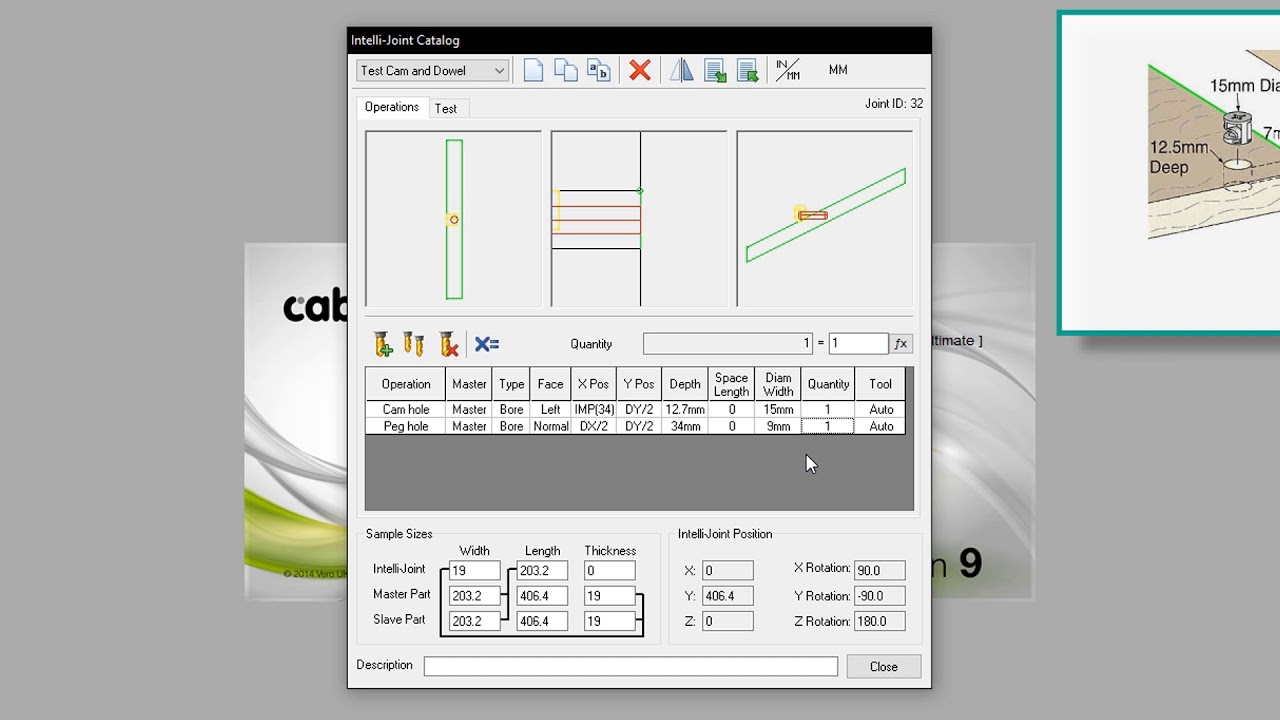

This eLearning component comes with a manual and an interactive CD designed to teach a wide range of topics regarding User Created Standards. This includes parameters, part orientation and reference points, formulas and their relationship to the Object Tree, adding custom parts to cabinets so that they will resize as the cabinet size changes, and creating an assembly of parts that will grow and shrink with the parent object and maintain This eLearning component comes with a manual and an interactive CD designed to teach a wide range of topics related to adding intelligence to parts in Solid.

For more information, please contact your Customer Service Representative at 80 or Intelligence Complete

0 kommentar(er)

0 kommentar(er)